AMOTHERM CONCRETE WB - Fire protection of concrete according to EN 13381-3:2015

Another important technical result has been achieved in the fire protection of reinforced concrete substrates.

Amotherm Concrete WB, a specific product for this type of substrate, has recently obtained the fire protection approval of load-bearing structural elements, such as beams and pillars exposed to bi-directional fire. The product is now also rated for the resistance class R 120 thus positioning itself as one of the most performing and complete products currently on the market.

From a technical point of view, Amotherm Concrete WB now has a complete assessment report, having reached class R 120 with both the minimum and maximum thickness.

As envisaged by the Standard itself (EN 13381-3:2015) in paragraph C.2.4, this allows interpolation between thicknesses with consequent optimisation of consumption and thereby containment of costs. Lesser costs both in terms of material and installation, but also in terms of speed of execution of the technical intervention.

It should be remembered that all this is possible thanks to the implementation of various experimental tests, which provide for the verification of elements exposed to fire with both mono-directional and bi-directional attack, such as:

- Elements exposed to fire with one-way attack

- large and loaded slab (12 m2) with application of the minimum protective thickness

- loaded and large slab (12 sqm) with application of the maximum thickness of protective coating

Results applicable to walls and slabs.

- Elements exposed to fire with bi-directional attack

- loaded column with application of minimum thickness of protective coating

- loaded column with application of the maximum thickness of protection

Results applicable to beams and columns

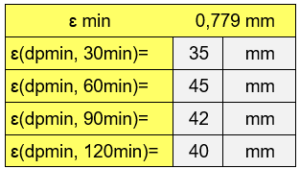

With these experimental results, the test laboratory is authorized and able to issue an evaluation report (and/or assessment) according to the classification standards EN 13501-2. The fire performances of the protective product are brought back and proposed to equivalent concrete values as shown in the following table.

It is undeniable that this standard determines a very complex and articulated test procedure. At the same time it is very pertinent and logical, as it verifies parameters such as stikability, i.e. the ability of the protective material to remain adherent and cohesive to the support for the entire duration of the fire, and spalling, i.e. the phenomenon of violent explosion of the concrete layer at the moment of heating.

The consequent equivalent concrete value, which can be correlated to the quantity of intumescent paint applied, offers the designer an immediate and easy-to-use tool within the analytical evaluation to determine the behavior of the element under examination in the heating phase.